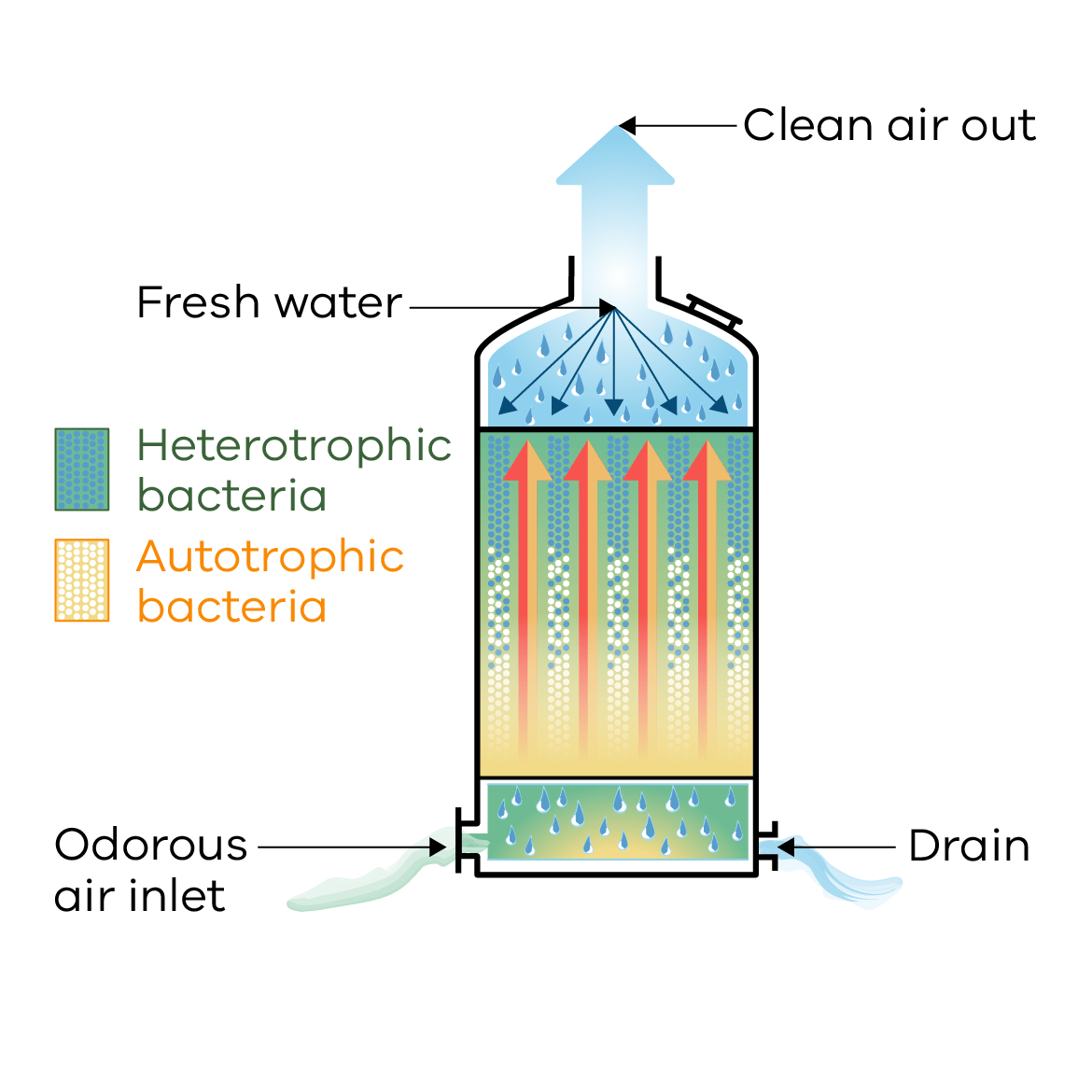

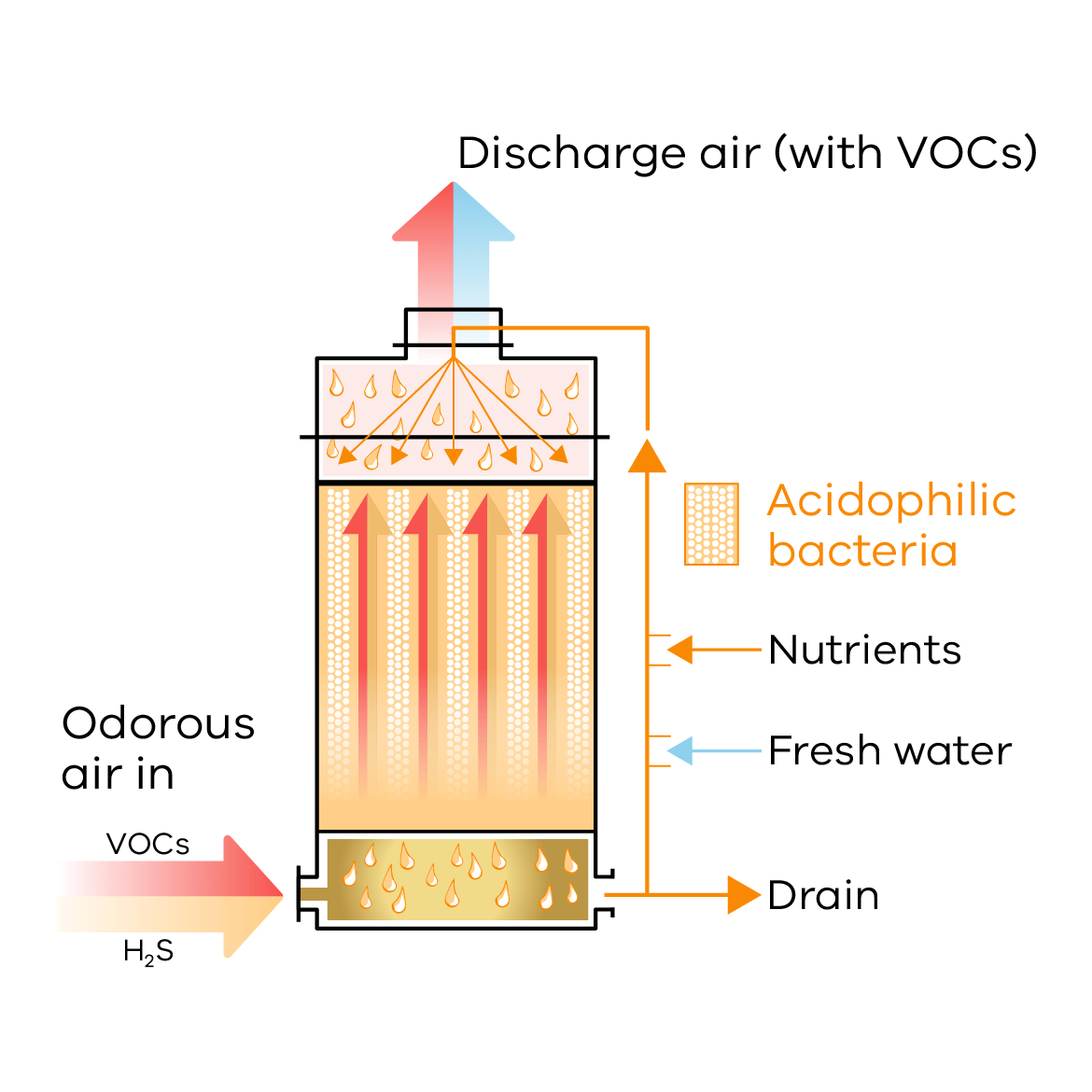

Bio-trickling filters and bioscrubbers are specialised odour treatment methods. They filter odorous air through microorganisms.

Bio-trickling filters combine properties of both biofilters and bioscrubbers in that they contain:

- filter material (media)

- water

- microorganisms that treat odour.

Bio-trickling filters and bioscrubbers differ from biofilters in that they:

- are smaller

- are enclosed systems

- contain inorganic media that does not need changing.

In a biofilter, the microorganisms grow within wood-based filter media. In a bioscrubber, the microorganisms:

- grow in a separate reservoir of treated water

- are recirculated with the water.

Bio-trickling filters and bioscrubbers can be more difficult and expensive to install than a biofilter. However, they have benefits over a biofilter:

- they can support a wider variety of microorganisms than biofilters, so they can filter more types of odours

- the media they use is synthetic foam or plastic packaging and rarely needs replacing

- they are energy efficient once installed.

Bio-trickling filters and bioscrubbers are specialised odour treatment methods. An expert needs to design them for your business.

Type of control

- Biological filtration

When to use a bio-trickling filter or bioscrubber

These filters work best:

- on large volumes with low or consistent concentration of odour

- when continuously operating.

If your site operates for less than 8 hours a day, 5 days a week, you should explore other odour treatment options.

Bio-trickling filters and bioscrubbers are suitable for:

- various volatile odorous compounds

- hydrocarbons, such as styrene or fatty acids

- sulfur-laden or chlorine-laden compounds

- nitrogenous compounds, such as ammonia.

Some of the industries that use bio-trickling filters and bioscrubbers include:

- industries that produce acidic gases

- water purification plants

- animal holding or processing facilities

- textile and tobacco industries.

Considerations and requirements

Similar to biofilters, bio-trickling filters and bioscrubbers are living odour controls. They need correct conditions to maintain optimum odour treatment.

Bio-trickling filters

To maintain your bio-trickling filter, you need to:

- continuously monitor the pH and temperature within the filter

- adjust or manage the pH within the filter by treating the water delivering nutrients to microorganisms

- keep the temperature between 15°C and 45°C – optimum temperature is between 30°C and 35°C

- have a qualified person clean the media if it becomes blocked by the biomass growing within it

- treat water that passes through the filter before releasing it into sewerage or drainage systems.

The wastewater from bio-trickling filters often contains sludge. You need to store and correctly treat this wastewater.

Refer to our Liquid storage and handling guidelines for information on storing liquids.

Find information on proper methods to handle hazardous waste in the WorkSafe Australia guidanceSafe handling of industrial waste: A practical guide for workplaces(opens in a new window).

Bioscrubbers

You need to:

- continuously monitor the pH and temperature within the bioscrubber

- maintain the pH within a broad spectrum and alter it if it becomes too high or low – you can easily adjust the pH as you recirculate water through the system

- keep the temperature between 15°C and 40°C – optimum temperature is between 30°C and 35°C

- treat the water containing the microorganisms once it has passed through the bioscrubber, before it is recirculated through the system.

Treating the water before recirculation creates sludge and wastewater. You must collect, store, handle and responsibly dispose of this sludge and wastewater.

Refer to our Liquid storage and handling guidelines for information on storing liquids.

Find information on proper methods to handle hazardous waste in the WorkSafe Australia guidance Safe handling of industrial waste: A practical guide for workplaces(opens in a new window).

Read more guidance on how to identify, manage and control odour from your business.

Differences between bio-trickling filters and bioscrubbers

Bio-trickling filters and bioscrubbers both:

- use microorganisms, media and water

- collect and force odorous or polluted air up through structured media within the vessel.

Bio-trickling filters:

- can be more effective at reducing odour than bioscrubbers because they do not recirculate water

- are as water efficient as a bioscrubber

- are useful where there is limited space.

Bio-trickling filters and bioscrubbers are similar, except that bio-trickling filters need fresh water and bioscrubbers recirculate water

Updated