Transporting industrial waste can pose a risk to human health and the environment if the waste is not properly managed and handled.

Under the Environment Protection Act 2017(opens in a new window), if you manage or control industrial waste to be transported, you must meet the duty of persons involved in transporting industrial waste.

If you are transporting reportable priority waste, you must also meet the duty of persons transporting reportable priority waste. This means you need a permission to transport the waste.

You need an A10a – Reportable priority waste (transport) – high risk permit to transport waste with the codes:

- B100 – acids in a solid form or acidic solutions with pH value of 4 or less

- E100 – oxidising agents, including peroxides

- G100 – ethers and highly flammable hydrocarbons, including petrol and jet fuel

- R100 – clinical and related wastes, including biomedical waste, not otherwise specified in Schedule 5 of the Regulations.

When you apply for an A10a permit, you need to make sure your vehicle can safely transport the waste specified.

The photos below show examples of the fittings and features that vehicles need to transport reportable priority waste.

Tanker and tanker trailer vehicles

Our Vehicle guidance: Tanker/tanker trailer outlines how to transport reportable priority waste in tankers.

Basic requirements

This example meets basic requirements, including a fire extinguisher and suitable spill kit.

Australian Standard

This example is fully compliant with Australian Standard for road tank vehicles for dangerous goods (AS2809.1:2023).

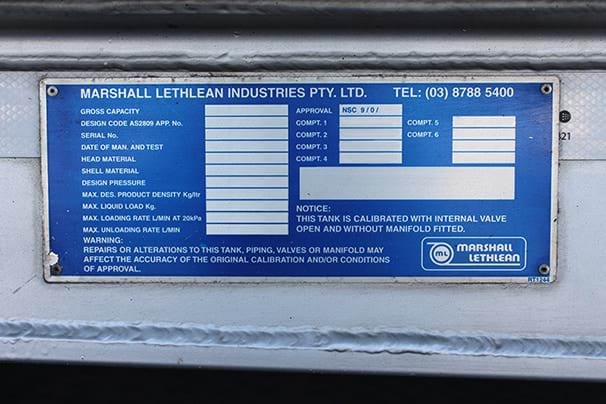

Tanker design approval

You must provide an AS2809 tanker design approval as part of your permit application.

Tanker baffles

Large compartments of tanks (greater than 2.5 m) should be fitted with baffles.

Small rear manhole

Tankers must have a manhole of at least 400 mm diameter.

Large rear door

Some tanker types come with a large rear door. This fitting is a deviation from AS2809. To see which waste codes you can transport in this type of tanker, refer to Vehicle guidance: Tanker/tanker trailer.

Closure points

Big manholes and rear doors should have a minimum of 6 closure points or an equivalent arrangement.

Full-width rear bumper

The rear bumper must extend the full width of the tank.

Rear fittings protection

The bumper must protect all external rear fittings on the tank. This means the fittings must not protrude beyond the bumper.

Sealed hose trays

Hose trays should be fully sealed.

Coaming

Coaming should meet Australian Standards.

Roof-mounted safety rail

The tanker must have a roof-mounted safety rail or fall protection device, under the Occupational Health and Safety Regulations 2017.

Shut-off valve

Capped valve

Non-tanker vehicles and trailers

Our Vehicle guidance: Non-tanker vehicles/trailers gives examples of vehicle controls, features and fittings for safety. This can help when you apply for a vehicle permit.

Basic requirements

This example meets basic requirements, including a fire extinguisher and suitable spill kit.

Load-restraining and load-securing devices

Secondary containment for liquids

Vehicles transporting liquid waste must must be fitted with secondary containment devices or portable bunded trays. This example shows a sealed and bunded floor and spillage collection sump.

Driver compartment separated

For some types of waste, the load must be physically separated from the driver’s cabin by a solid partition.

Lockable load compartments

For waste codes R100, R120 and R140, either the load compartment or the waste containers must be lockable.

Waterproof PVC tarpaulin cover

All bulk loads must be fully contained or covered by a suitable PVC tarpaulin cover or equivalent.

This does not apply to asbestos waste transported in secondary containers. It also does not apply to large containers.

Freight container and bin-securing devices

Hook lift devices must be securely fastened with tie-downs installed lengthwise. The bin should be aligned with the chassis for transport.

Tailgate and tipping body

There should be no gaps between the tailgate and the tipping body.

Secure load area

The load area should be leak proof, with no holes or gaps.

Emergency information panels (dangerous goods)

Class labels (dangerous goods)

Emergency information panels (30XY waste)

Updated