This guidance sheet is part of a series of guidance sheets. It should be read with our odour guidance for businesses.

On this page

Description

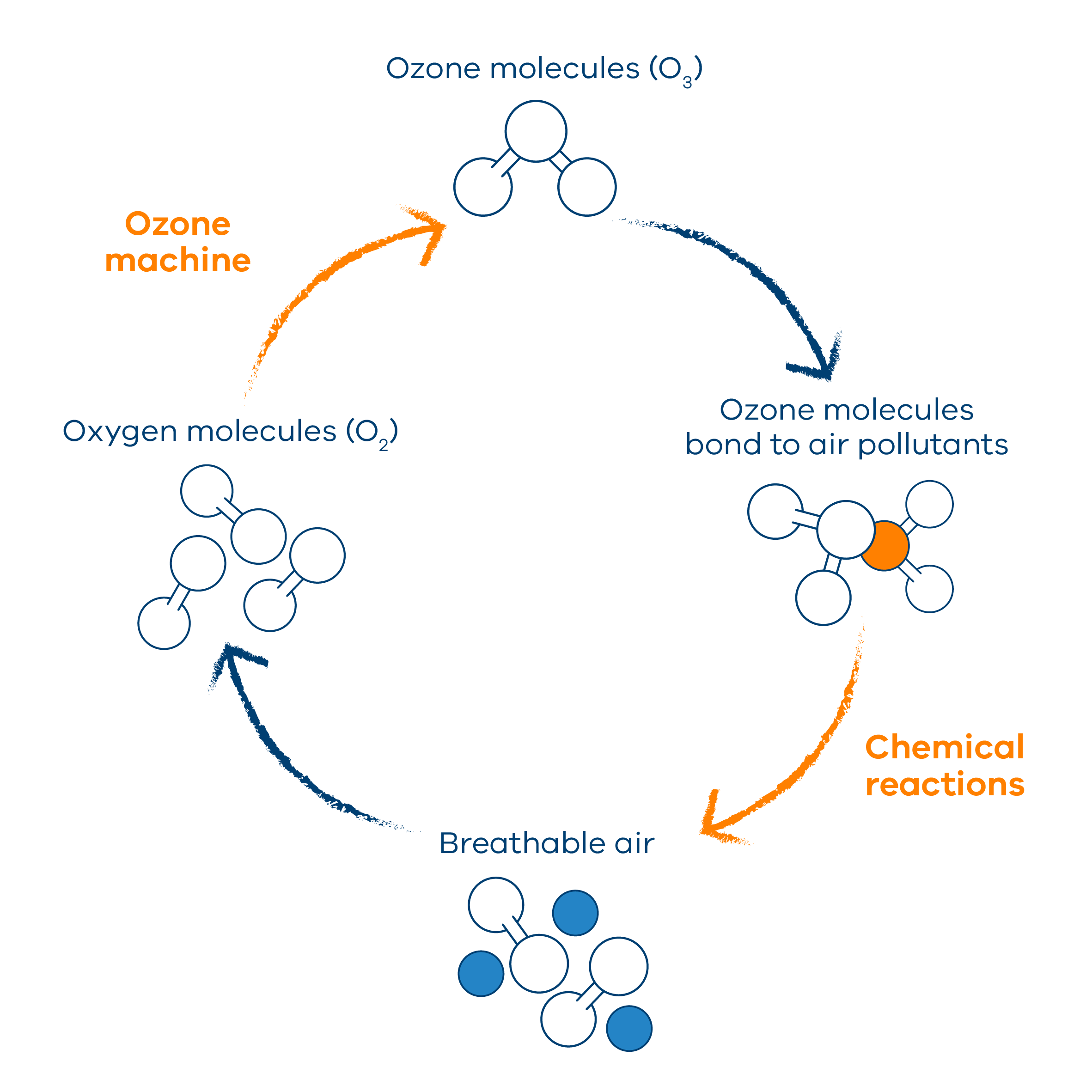

Ozone chemically reacts with inorganic compounds like hydrogen sulphide, or volatile organic compounds (VOCs) within exhaust gases, producing non-volatile compounds and water. This process eliminates odour. Ozone treatment is an emerging technology, and implementation involves the use of an ozone machine to either electrically or chemically create ozone. Emerging studies show that ozone treatment can be an environmentally friendly, effective treatment for airborne odorous particles.

Type of control

Chemical.

When you would use this

Ozone treatment is still an emerging technology and the full scope of its capabilities are not yet realised. For a better understanding of whether ozone treatment is right for you or not, engage a suitably qualified person. See the engaging consultants page for further information on finding a professional suitable for your business.

Suitable for: in general, while ozone treatment can be effective on some inorganic compounds, it is more broadly used in the control of volatile organic compounds.

Industries that would use this: ozone treatment has been commonly used in the destruction of odours emanating from sources such as grease traps, piggeries, composting, livestock yards and processing etc.

Details and considerations

Using an ozone machine, ozone is generated using either electricity (cold plasma) or ultra violet light. Some systems may use titanium dioxide (TiO2) as a catalyst, or water vapor that rapidly converts to hydrogen peroxide or hydroxy free radicals, breaking down airborne odours.

Cold plasma/electricity generated systems

Cold plasma systems work by releasing electricity into a charged environment. This environment creates reactive compounds such as ozone, hydrogen peroxide and hydroxy free radicals which destroy the odour compounds in the waste gas stream.

UV & catalytic system

These systems tend to work best on odorous liquids. A UV generating lamp is kept close to both the liquid to be treated and a titanium dioxide coating on the walls and baffles of the system. The titanium dioxide acts as a catalyst between the ozone and the liquid to generate hydroxyl free radicals. It is very important that the UV lamp within the system is positioned correctly. If it is not, then the odour eliminating reactions will not be fast enough to eliminate all of the odour present, or at all.

There are a few considerations to keep in mind when deciding whether to implement an ozone treatment system within your business:

- As ozone treatment is relatively new, it is advised that you follow EPA's information about engaging consultants, and speak to a suitably qualified person when deciding on this treatment for your business or site.

- Ozone treatment may not be as widely available as other odour control methods. This may mean that parts, upkeep, and suitably qualified maintenance professionals will be difficult to find in your area.

- Studies have largely shown that ozone treatment is most effective on organic odours, if your business or site produces inorganic odorous compounds then this treatment may not be right for you.

- As these systems can be difficult to set up, it is not typically a treatment solution that you can implement yourself, this will mean some costs may be required for consulting, installation, and maintenance.

Read more

This page was copied from EPA's old website. It was last updated on 20 June 2019.

Reviewed 1 October 2020